Wow, where to start this week….. So many things have been done recently.

I’ve cut out a section of the front bumper, and raised it up higher. This creates a diverging ramp under the nose of the car, speeding up the airflow creating a low pressure under the car, sucking it to the ground (well that’s the theory anyway!)

These next two pics show the ramp a little bit more clearly.

The sections in front the wheels stay low to the ground, to divert the airflow around the front tyres, reducing drag.

It was then time to keep working on the rear floor, making supports to hold the floor up. Now that there is nothing left in the back of the car, I had to make mounts that connect the floor to the chassis.

This one is to hold up the back edge of the diffuser.

These ones are to mount the other end of the diffuser, just in front of the back wheels,

Next on the list of things to do is to build the new firewall. This will be a new section behind the drivers seat – think of the inside of a single cab ute. This will seal off the passenger compartment from the fuel tank, exhaust, diff etc that is now exposed in the rear of the car.

The middle upper section will be clear (lexan to be precise), and due to the complex nature of the roll cage it was too difficult to make a single lexan sheet that would span the whole width of the car. So instead i made two side panels to go around the bars from one side, then the lexan can join these panels from the other side.

The next step was to make the lexan panel. After cutting it all out, I painted the outer edge black, where it would be glued and bolted to the car.

The next item on the list was a new fuel tank. I wanted to build a new tank that was lighter and would not fuel surge even with as little as 1/2 a litre of fuel left.

When I built the last tank I was still driving the car to places like Collie for events, so it was sized accordingly (28L to be exact). Now that its a trailer queen, it only needs 8-10 litres max to complete 5 laps at Waneroo.

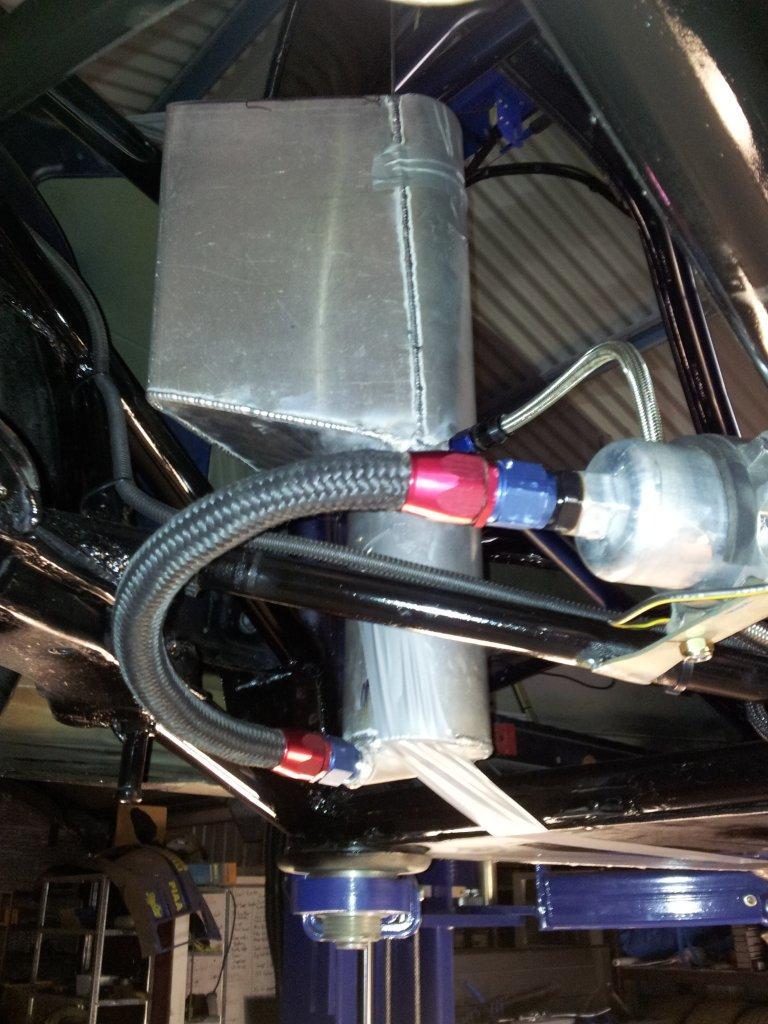

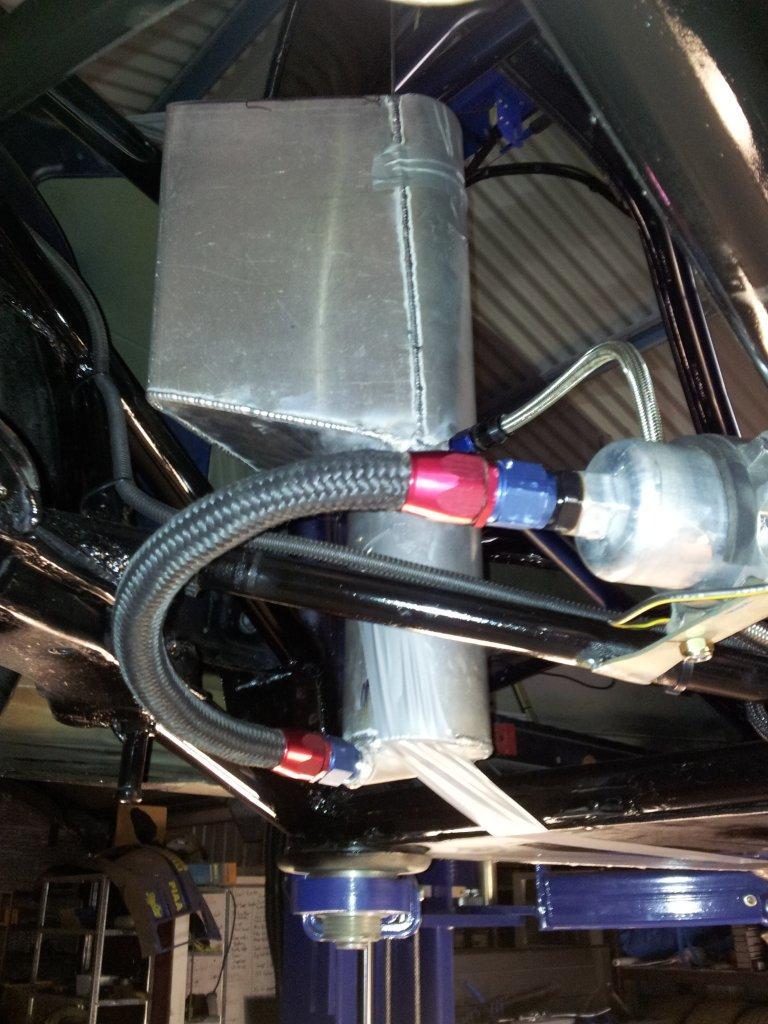

Here is the first part of the tank. The tube is to ensure that there is no surge, with the larger part at the top to ensure sufficient capacity.

The bottom section in more detail. The bottom outlet is the feed to the fuel pump, the upper one is the return from the motor. These outlets are spaced out to make sure the fuel stays as cool as possible (the fuel returning from the motor has been heated from the heat in the engine bay), but at the same time making sure that the fuel being returned to the tank can’t get caught in a corner of the fuel tank that is not near the fuel outlet. Yes, trying for the best of both worlds again.

My welding on alloy is getting better and better all the time too. 🙂

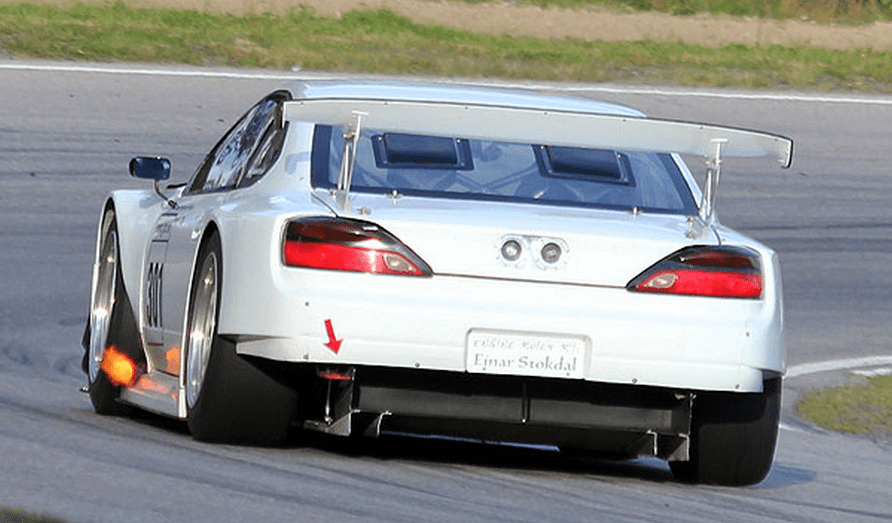

This is how the tank will sit in the car.

Had to re-jig the fuel lines as well. The tank is now a lot closer to the front of the car now, so I had to shorten them all.

One last view inside the tank before the top goes on.

Wow, I’m tired after that post!