First job of the weekend was on Friday night, putting some flat black paint on the A pilar and Carlos bar, helps to make them ‘disappear’ when you are looking out through the front window.

On Saturday, once the paint had dried it was time to get inside and start getting all of the brake and fuel lines done.

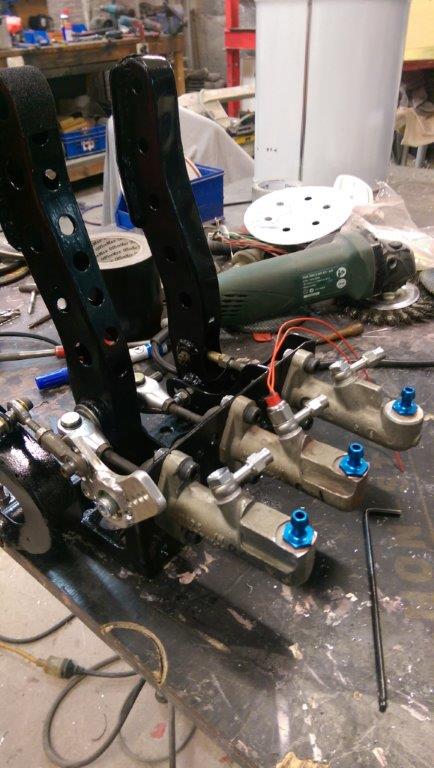

Got the handbrake mounted, rear split valve in place.

Pedals all mounted and plumbed in.

CoDrivers seat and belts all in.

A bit of colour coding to the Velo logo, just because….

Engine, gearbox and front cross member all in, front suspension all attached.

New top and bottom radiator mounts made, rad repainted and fan fitted.

Tailshaft and exhaust painted and mounted.

And on its own feet for the first time since the stock, crashed shell was pushed into the shed 2 years ago!

Now all I have to do is paint it, make the wiring loom, fit all of the other interior bits like dash, ECU, map light, trip computer, intercom, medical kit, triangles, cage padding, battery mount, foot rests for both sides, sump gaurd, get the engine tuned get it CAMS log booked, road licensed, etc, etc etc….. I’ve got a month, so……….